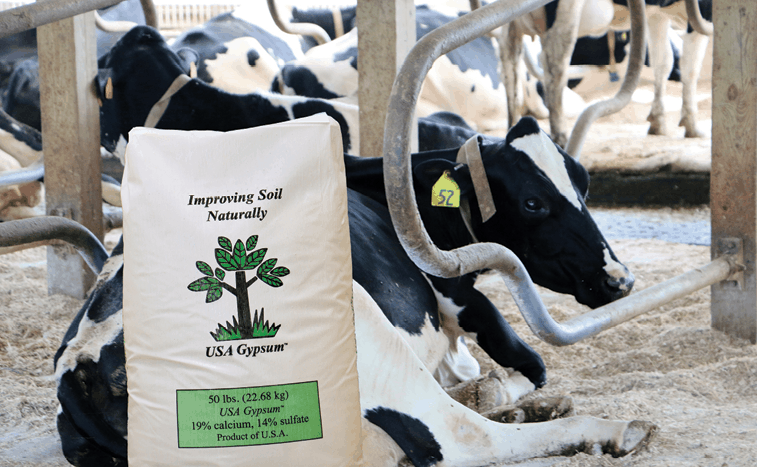

Photo Credit Laura Jean Watson Photography

While recycled gypsum is widely embraced today for its use as a soil amendment, agricultural bedding additive and for other applications, it wasn’t too long ago that the potential for drywall recycling was largely untapped.

Terry Weaver, president of Denver, Pennsylvania-based USA Gypsum, says that his entrée into the world of gypsum recycling was largely a matter of happenstance.

In the mid-1990s, Weaver was making a living running a construction company and operating farms. Michael W. Brubaker, who was serving as Weaver’s agronomist at the time, began to explore the potential for improving the quality of agricultural land by introducing gypsum to serve as a soil amendment, conditioner and fertilizer.

“Michael Brubaker came up with this concept of using gypsum to improve the soil, but there was none available nearby. That was prior to even the advent of FGD gypsum, so you were stuck with relying on mines from Nova Scotia or Michigan as a source,” Weaver says. “He started testing the core of drywall around 1996 to see if it was suitable, and it appeared like it was, so he set about to develop a system to remove the outer paper of the drywall from the drywall core, which is an important part of what you do in gypsum recycling, and he came up with a nice little system to do that, but it was small. In 1998, USA Gypsum was formed.”

Shortly after developing this system to recycle drywall, Brubaker decided to sell his agronomy business and run for state Senate, which he was ultimately successful at.

Needing someone to take over the recycling operation, Brubaker turned to Weaver to take the reins.

“He called me and just said, ‘Hey, I don't know if this is something that could be scaled up, but do you think it could be a real business?’ After thinking about it, it seemed like a good idea to me, so I decided to agree to take over the operations,” Weaver says.

With a large extended family and friends in the region making a living in agriculture, Weaver was able to find early adopters interested in using recycled gypsum. Soon, demand in the area began to outpace the production capabilities of that first recycling facility, resulting in Weaver moving the business to a larger facility in 2000.

It was around this time that Weaver, who was still managing a construction business, decided to go all in on the new recycling venture.

“I didn't put all my eggs in that [recycling] basket for a little while because I didn't know how far we could scale it up, but within a couple of years, I said to myself, ‘Yeah, I think this is going to be OK,’” he says.

Growing its customer base

Due to USA Gypsum’s rural location, the initial end markets were almost exclusively agricultural. However, over time, Weaver began to search for and find other outlets for the gypsum the company extrapolated from incoming wallboard generated from C&D processors, manufacturers, and construction and building material suppliers.

“Our markets initially were all agriculture because that was the purpose of starting the business, but over the years, we developed some other markets,” he says. “The three big users of gypsum are first wallboard manufacturers—that's by far the largest. Second is for the production of Portland cement, and third is agriculture and incidental uses. We started supplying the cement industry around 2003, and that was our first instance of branching out from agricultural customers. And then over the years, other people have found us for a variety of things, anything from reclaiming contaminated soils to clearing up muddy ponds. We have a lot of different applications.”

More recently, Weaver says that the company began to supply some wallboard manufacturers with gypsum. However, the inherent economics of supplying wallboard manufacturers can make it a challenge for recyclers, Weaver notes.

He says that one of the initial challenges of supplying wallboard manufacturers is that many manufacturers set up shop adjacent to a port or power plant to ensure an economical source of gypsum is available. Additionally, the vast quantities of gypsum that these customers require make it difficult for recyclers to meet the demand. Then there is the issue that different consistencies of recycled gypsum might require manufacturers to take additional steps to blend or handle the material to make it right for their processes and equipment.

On the flip side, Weaver notes that the growing demand for companies to champion sustainable practices and embrace a closed loop model of operation has helped USA Gypsum market its products to these customers.

“I believe personally that in the future, [the closed loop approach] is going to be an important part of gypsum drywall recycling, and that really that needs to happen in order for it to really be scaled up nationwide to where it becomes a standard practice,” he says.

-001_fmt.png)

Improving the product

Part and parcel of finding markets involves continuing to refine processing practices, Weaver notes.

USA Gypsum uses various magnets and a pick line to remove incidental non-magnetic contaminants and other debris from the 200 to 250 tons of incoming material the company accepts every day between its two Pennsylvania-based facilities. While Weaver keeps the specifics of the company’s sorting equipment and processes close to the vest, he notes that the company is constantly working to evaluate technological advances for improved separation capabilities.

In 2015, the company constructed an all-new process plant, which marked another evolution in the company’s ability to handle incoming material.

“I think the equipment that we have installed right now would be the fifth complete version we’ve used since our founding. By that. I mean a dramatically different form of equipment. There's been this progression both in volume [we’ve been able to process] and quality of materials we are able to generate, and we just keep on tweaking it to get it right,” he says.

Weaver says the company is currently looking at investing in some new equipment to further improve the company’s separation efficiency. Down the line, he says the company is also keeping an eye on the economics and potential for robotic sorting to replace the company’s manual sorting processes, but Weaver wants to see more to ensure the technology provides an ROI before making the investment.

USA Gypsum’s commitment to continually refining its sorting processes, as well as its capacity to create new gypsum products for different applications, has allowed the company to diversify its reach.

Weaver says that due to the nature of transportation costs, roughly 60 percent of the company’s volumes are shipped within 150 miles. However, Weaver says that the company’s work blending materials to produce value-added products and packaging it in bags and super sacks has been an important aspect in helping the business reach new customers.

He says USA Gypsum’s rigorous devotion to finding end market solutions can be traced back to the origins of the company.

“Our entry into the business and focus on the business has always been end markets, not because we're smarter than anybody, but because it was a necessity,” he says. “A lot of people I see approach the business are from the recycling side and the focus just naturally tends to be on acquiring material and then cost avoidance on the outbound side. We just started on the other foot and stayed focused in that way. I think that's why we're one of the few standalone drywall recyclers in the country.”

Beyond the products themselves, USA Gypsum’s approach to serving the customer is something Weaver says has helped differentiate the company from large traditional gypsum suppliers. He says USA Gypsum works to accommodate custom orders and provide personal service in a way that these companies might not be able or willing to do.

“That's where we've found a niche of sorts—working to fill orders for those customers who might not be regular users. Maybe it’s someone doing work clarifying ponds or someone who owns a golf course and is looking for a soil amendment. Being able to step up to fill these one-off and custom orders has been a real value-added side of our business,” Weaver says.

“I think [providing quality customer service] is how we’ve worked to serve our niche clients,” he adds. “The personalized service that we can offer is a good match and we pride ourselves on that. We try to answer the phone, we try to be available to answer questions and we're pretty open trying to be helpful. We've developed a nice little business out of that.”

This article originally appeared in the July/August issue of Construction & Demolition Recycling magazine. The author is the editor of Construction & Demolition Recycling magazine and can be reached at aredling@gie.net.

Latest from Waste Today

- Rancho Las Virgenes Compost Facility—Calabasas, California

- Optimize wet waste management with Sebright Products High-Density Extruders

- Plum Creek announces new regional sales manager

- WM reports strong Q4 earnings

- Washington state legislature introduces bills to create recycling refund program for beverage containers

- Lee Zeldin sworn in as new EPA administrator

- C&D World session preview: Optimizing Plant Operations with best practices for efficiency and success

- Hyva launches new rear loader