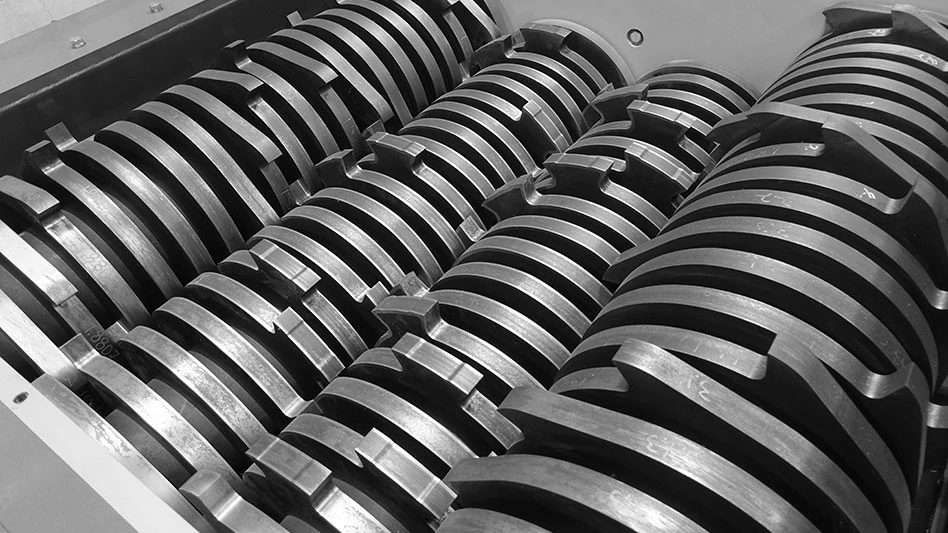

Photo courtesy of SSI Shredding Systems

You are the proud owner of a new shredder. This could be because you recently started a new business or expanded an existing one. Now that you have this new machine, you are probably asking yourself, “How do I maintain this thing to get the most out of my investment?”

With a variety of shredder types and an even wider array of applications, no one set of rules applies to shredder maintenance. The most crucial factor in predicting the performance and longevity of your shredder is to select the right shredder for the application.

When shopping for your shredder, it helps to answer a few key questions:

- What material am I shredding?

- What size will the material be when I feed it into the shredder?

- What size will it need to be when it is discharged?

- How much of it will I need to process?

Two-shaft shredders

If you chose a two-shaft shredder, congratulations! You have the most adaptable style of shredder technology. The reasons to purchase this type of shredder likely include its versatility, high thruput capability and low operating cost.

The versatility of two-shaft shredders comes from their low rotary speed and reversing capabilities, reducing the risk of damage to the machine when it encounters nonshreddable materials. This makes them well-equipped to process contaminated material streams.

The low operating cost comes from the design of the two-shaft technology. The long cutting edges of the heavy-duty cutters spread the shearing action over a larger area, extending the machine’s maintenance interval. The lower rotary speeds allow the shredder to maintain power while consuming less energy.

Single-rotor shredders

If you are using a single-rotor shredder or grinder, you likely selected this machine because your application requires strict particle size control. Single-rotor shredders have a relatively lower upfront cost and, when properly employed, offer the most cost-effective option for uniform sizing of “clean” materials. Material streams are considered “clean” when they are devoid of unexpected, nonshreddable contaminants.

Single-rotor shredders typically operate at speeds of 80 to 110 rpm or higher. This is more than the 10 to 25 rpm of rotary shear shredders. Given the higher rpm and smaller cutting surface, cutters wear faster and require more frequent maintenance. Luckily, servicing a single-rotor shredder often is quicker and simpler when compared to its rotary shear counterparts. Cutters in a single-rotor machine can be rotated up to four times before needing replacement.

Four-shaft shredders

Four-shaft machines combine the versatility and robustness of a two-shaft shredder with the particle size control of a single-rotor shredder. If you bought a four-shaft shredder, you likely decided on your machine for its ability to handle difficult materials while still delivering uniform particle size.

Four-shaft shredders also are rotary shear shredders, sharing many of the same advantages with the two-shaft machines.

While four-shaft shredders have a longer maintenance interval when compared with single-rotor machines, servicing them can be more expensive and time consuming.

Putting in the time

In short, single-rotor shredders require more frequent, albeit simpler and less expensive, service. Whereas, four-shaft shredders require less frequent but more expensive and labor-intensive maintenance. Depending on the application, the relative operating cost can favor either style. It is important to consider if your operation is set up for service. A company with an experienced service team or other equipment requiring service could find the shorter interval of the single-rotor shredder less of an issue. However, if you do not have the personnel to perform the maintenance, infrequent service could be more appealing and easier to manage.

How often you should expect to service your machine depends on your application. Operational hours, thruput rate and the physical qualities of the material being shredded all play a role in dictating how often your machine will require service.

For example, a shredder processing mixed plastics could require a cutter change only once a year. While a tire processor with the same machine could need to exchange cutters every month.

How can you tell if it is time for maintenance?

Unless you have a routine maintenance schedule in place, the best way to know is by monitoring the thruput rate. If your productivity dips below an acceptable threshold, or if the shredder is reversing more than tolerable, it is a sign that is time for maintenance.

Performing maintenance on a shredder means downtime. To optimize that downtime, plan to service or replace multiple shredder components at once. For instance, if you are changing cutters, you should check your gears, fluids, bearings and seals ahead of time to see if they need replacing along with the cutters.

In nearly all cases, it is cheaper and less time-consuming to employ a preventive maintenance plan than to wait for a critical failure. Operations managers at shredding facilities should allot time in the production schedule for shredders to be serviced and inspected.

Cutter health

Rotary shear machines require not only sharp cutters but a tight cutter stack as well. A loose stack allows the cutters to shift during operation, causing accelerated and uneven wear. In extreme cases, a loose cutter can even collide with an opposing cutter. When the stack is loose, dirt and other abrasive fine material work their way between the cutters and spacers, wearing away the face. Face wear makes cutters harder to rebuild, shortening their life.

Single-rotor shredders create their shearing action when the tip of a square-shaped cutter passes through a fixed anvil. As the cutters and anvils wear, the gap between them grows, reducing the production of the machine. The increased gap also generates friction and heat, which can cause the shredder to jam and increases the stress on its components.

While preserving cutter health is important, other elements of the shredder should be monitored.

In the ongoing effort to reduce load on the shredder, the cutting chamber and discharge chute should be inspected for blockages and cleared prior to starting the machine.

Shredders, like cars, use lubricant to reduce friction between gears in the drive train. Oil should be regularly inspected. Degraded oil or oil with a great deal of debris should be drained and replaced. Old oil loses its lubricating properties, resulting in increased heat during operation. This heat can damage the gears. Additionally, contaminants such as metal shavings in the oil are abrasive and increase the wear on gears.

A multitude of factors from application requirements, shredder specifications, to personal preference dictates the maintenance interval of your machine. Having clear production expectations gives you a threshold for triggering maintenance. If unsure about the best method for maintaining and optimizing your shredder performance, contact experienced shredder professionals who can use their experience and expertise to inform your decision.

This article was submitted by SSI Shredding Systems, Wilsonville, Oregon.Latest from Waste Today

- Startup proposes medical waste facility in Alabama

- Mount Vernon, Ohio, city council tightens waste hauling regulations

- Retail associations sign MOU to form producer responsibility organization for textiles in California

- Republic Services partners with EDL to provide RNG for San Antonio buses

- WM opens 12 recycling facilities in 2024

- Plastics recyclers report difficult conditions

- BTS Bioenergy opens Maryland Organics Recovery Center

- Meadow tabs aluminum as key to boosting beauty sector recycling