RES Polyflow LLC has selected the facilities services and construction contractor Shambaugh & Son L.P., Fort Wayne, Indiana, to provide engineering procurement and construction management services to design and build a plastics-to-fuel energy-recovery facility in Ashley, Indiana. The Indiana plant will be RES Polyflow’s first regional plastics-to-fuel energy-recovery facility.

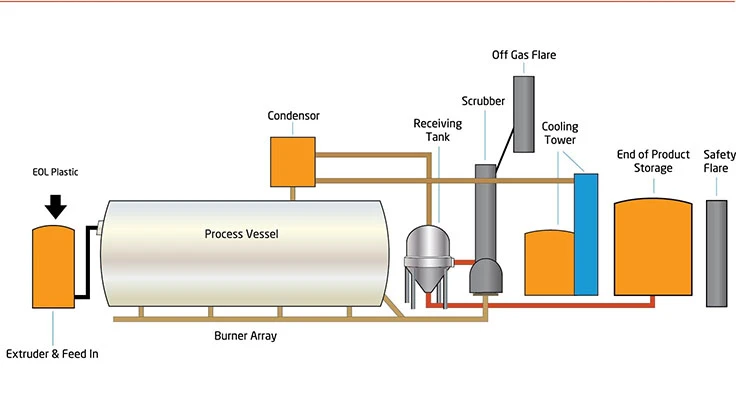

The Indiana plant will use RES Polyflow’s patented process to convert nonrecycled plastic into petroleum products, such as ultra-low sulfur diesel and gasoline. Shambaugh & Son will manage the process installation and the startup of the plant.

“RES Polyflow is very excited to work with the team at Shambaugh & Son for the successful commercialization of this world-changing technology,” says Jay Schabel, CEO of RES Polyflow. “Our combined focus is properly aligned as all of the participants are excited about the potential this plant brings to their company as well as for a cleaner planet.”

Paul Meyers Jr., CEO of Shambaugh & Son, says, “We’re pleased to have been selected by RES Polyflow to help actualize a commercial facility of advanced technology, scope and production. Shambaugh & Son has a wealth of experience in designing and building highly technical, commercial facilities to detailed specifications.”

When operational, the Indiana facility will produce 21 million gallons of petroleum blend stocks each year from 100,000 tons of locally generated plastic scrap. RES Polyflow says the 25-acre site will be the largest commercial plastics-to-fuel energy-recovery facility in the world. The company adds that the Ashley location will serve its long-term growth plans in the Midwest by serving as a regional hub for upgrading the liquid material generated by other RES Polyflow production sites being planned for surrounding Midwestern states.

Schabel says RES Polyflow already has secured contracts with suppliers to meet the plastic scrap needs of the facility. He says the supply base will run from Chicago on the west to Toledo, Ohio, on the east. Some of the types of plastics the facility will consume include shrink labels and bottle caps. The company also will pull some plastic scrap in from postindustrial sources.

The project is expected to be completed by the middle of 2018.

Latest from Waste Today

- IWS acquires Seaside Waste Services

- VLS Environmental Solutions appoints new national rail solutions sales director

- Casella Waste to promote president to CEO

- Convertus finalizes permits for Ontario AD facility

- Defunct electronics recycling companies ordered to pay $3M for hazardous waste violations in Ohio

- Tacoma, Washington, launches smart camera technology pilot

- Pride Disposal sees efficiency gains with Hydrotex BIO-XPL hydraulic fluid

- Techbros launches AI-integrated electronics processing facility