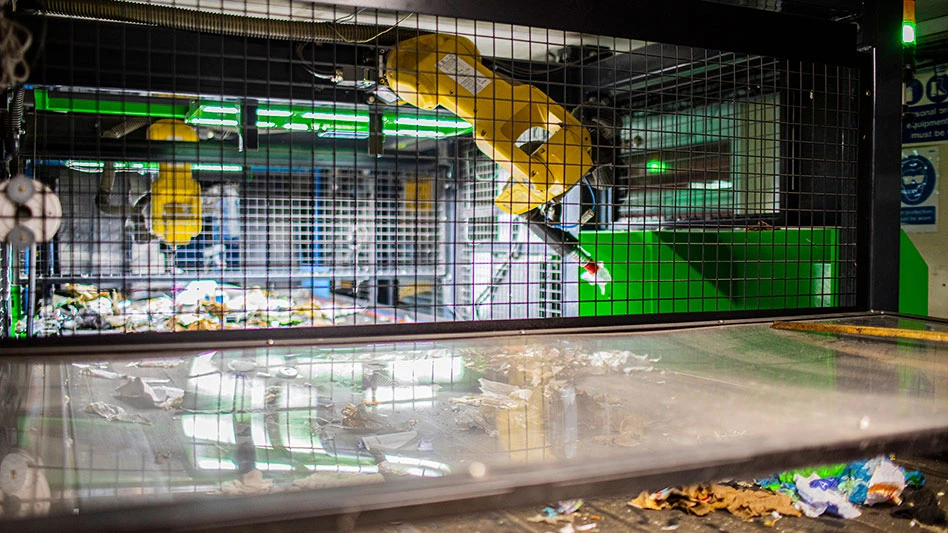

Photo courtesy of Recycleye

Panda Ireland, headquartered in Dublin, installed four robots from London-based Recycleye at its Ballymount material recovery facility (MRF) in November 2022. The artificial intelligence- (AI-) powered robots automate the MRF’s quality control operations, with two of the four robots removing contamination from the mixed paper line, a third removing contamination from the aluminum can line, and the last recovering beverage cartons from a residual line.

Panda’s Ballymount MRF is Ireland’s largest mixed dry recycling facility, processing the commingled recycling collected from 400,000 homes in Dublin and the surrounding counties. It recovers paper, plastics, aluminum and steel for reuse. It provides an important service in helping Ireland meet sustainability goals.

Labor challenges prompted the site to install the four AI-powered robotic arms over its quality control lines, an application that Recycleye says is the first of its kind in Ireland. The system comprises a camera that sits atop the conveyor belts and identifies every item in the waste stream by object and material using computer vision algorithms, which then instruct the corresponding robotic arm to pick the item and shoot it into the correct bin. This provides Panda with consistent picking, meaning its operations are more profitable, and also scans 100 percent of the material stream to provide compositional trend insights to the MRF.

“The Recycleye robot system has provided a cost reduction and allowed us to achieve a more accurate picking solution at certain points in our process," says Liam Dunne, head of project management office at Panda.

The aluminum line robot has automated a previously manual job, resulting in a labor cost reduction, as the robot can pick consistently and continuously across both shifts. Meanwhile, the residual line robot is recovering beverage cartons that were not previously picked for resale, creating a new revenue stream for Panda’s MRF, according to Recycleye.

Recycleye says its light, retrofittable solution is attractive to MRFs.

“The single biggest reason we decided to go with Recycleye is that they fit their machine into our existing infrastructure,” Dunne says. “The installation process was carried out over two weekends, out of production hours, within our schedule. All we had to do was prepare the area—Recycleye looked after everything else.”

Tom Harrison, technical sales manager for U.K. and Ireland at Recycleye, says, “We are proud to support the Panda team in automating their sorting operations to achieve more reliable resource recovery through a robust, cost-effective and retrofittable solution.”

“Robotics and automation are key to the future of waste management because they bring about efficiency in our sorting process, by delivering repeatability and reducing costs,” Dunne adds.

Latest from Waste Today

- Deep Green to acquire Junk King franchises

- The Recycling Partnership urges Congress to enact tax credit for recycling infrastructure investment

- Hendrickson to build a solar farm to power bumper plant

- HDR to develop materials management plan for Michigan county

- Toppoint Holdings closes $10M IPO

- Recycling company CEO among those indicted in Oakland, California, bribery case

- Atlas, Mantsinen lines now available at Mid-Atlantic Komatsu locations

- Terex Recycling Systems, ZenRobotics expand into Hungary