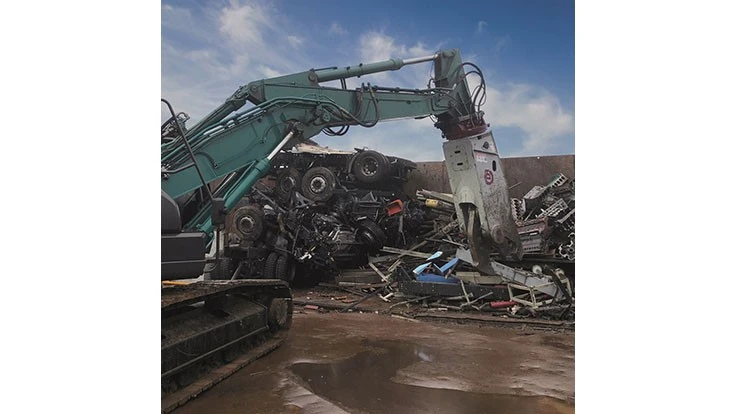

Kinshofer USA, Sanborn, New York, has introduced the DXS Series of hydraulic mobile excavator shears, which the company says features industry-leading power-to-weight ratios, jaw opening sizes, cycle times and hydraulic efficiency. The series, available in the DXS-40 and DXS-50 models, is suitable for scrap processing, tire recycling and demolition. Both models are also available with integrated Fuchs Quick Connect (FQC) system.

“We designed the DXS Series to enhance contractors’ productivity and ROI (return on investment,” says Francois Martin, Kinshofer North America general manager. “Traditionally, more power means a larger cylinder, which results in a bigger, heavier shear and, often, a larger machine. The DXS-50 has the same-sized cylinder as shears in the same weight class but with 25 percent more power, allowing our customers to achieve higher performance without investing in larger carriers. This saves them money upfront while improving their ROI with the attachment’s production-boosting qualities,” he adds.

Kinshofer’s DemaPower 2.0 cylinder technology gives the DXS-50 the same power as shears two sizes larger, according to the manufacturer. The cylinder uses four chambers instead of the two found in other shears, resulting in 20 percent more surface area within the cylinder. That allows the DXS Series to exert up to 25 percent more power from a smaller attachment, resulting in the best power-to-weight ratio in its size class, Kinshofer says. The 9,920-pound (4,500-kilogram) DXS-50 features a closing force of 1,203 tons (10,700 kilonewtons) compared with 922 tons (8,210 kilonewtons) from its 9,020-pound (4,100-kilogram) predecessor, the DRS-45.

Compared with the models from Kinshofer’s established DRS Series, the DXS-40 is marginally heavier than the DRS-30 and has the cutting performance, jaw opening and depth of the DRS-45. Like the DRS-45, the DXS-50 is suited for 25- to 35-ton carriers when boom mounted, and 32- to 50-ton carriers when stick mounted, according to the manufacturer. This means contractors can achieve a closing force equivalent to shears two sizes up, requiring a minimum 32-ton carrier, on an excavator weighing 7 tons less. In addition, the cylinder technology allowed the company to design the DXS-50 with a jaw opening 29.2 inches (74 centimeters) wide and 30.7 inches (78 centimeters) deep, which Kinshofer says is larger than any other shear in its weight class, as well as some larger models.

The DXS-50 reduces carrier fuel consumption by up to 20 percent compared with competitive shear models, the company says. The attachment’s design allows it to function normally when the carrier is set in economy mode, achieving the same performance as a competitive shear on an excavator running at full throttle.

The DXS-50’s high power-to-weight ratio makes the attachment well-suited to top-down demolition, Kinshofer says. Contractors can use smaller carriers and the attachment’s light weight and cylinder technology improve fuel efficiency while the excavator arm is fully extended. In addition, the attachment features a narrow frame to allow operators to better see their work.

Double-acting speed valves coupled with the cylinder technology gives the DXS-50 cycle times as fast as 5.5 seconds, 50 percent faster than any model in the attachment’s weight class, according to Kinshofer.

Rotation-equipped models feature 360-degree continuous rotation on an oversized slewing ring to bear high forces, shock loads and bending. According to the manufacturer, the rotation model also includes heavy-duty motors for maximum rotation torque.

The shear is designed with convenient service openings for fast access to shear hoses and hydraulics. The DXS-50 also features a piercing tip that can be welded again and replaced.

Latest from Waste Today

- Deep Green to acquire Junk King franchises

- The Recycling Partnership urges Congress to enact tax credit for recycling infrastructure investment

- Hendrickson to build a solar farm to power bumper plant

- HDR to develop materials management plan for Michigan county

- Toppoint Holdings closes $10M IPO

- Recycling company CEO among those indicted in Oakland, California, bribery case

- Atlas, Mantsinen lines now available at Mid-Atlantic Komatsu locations

- Terex Recycling Systems, ZenRobotics expand into Hungary