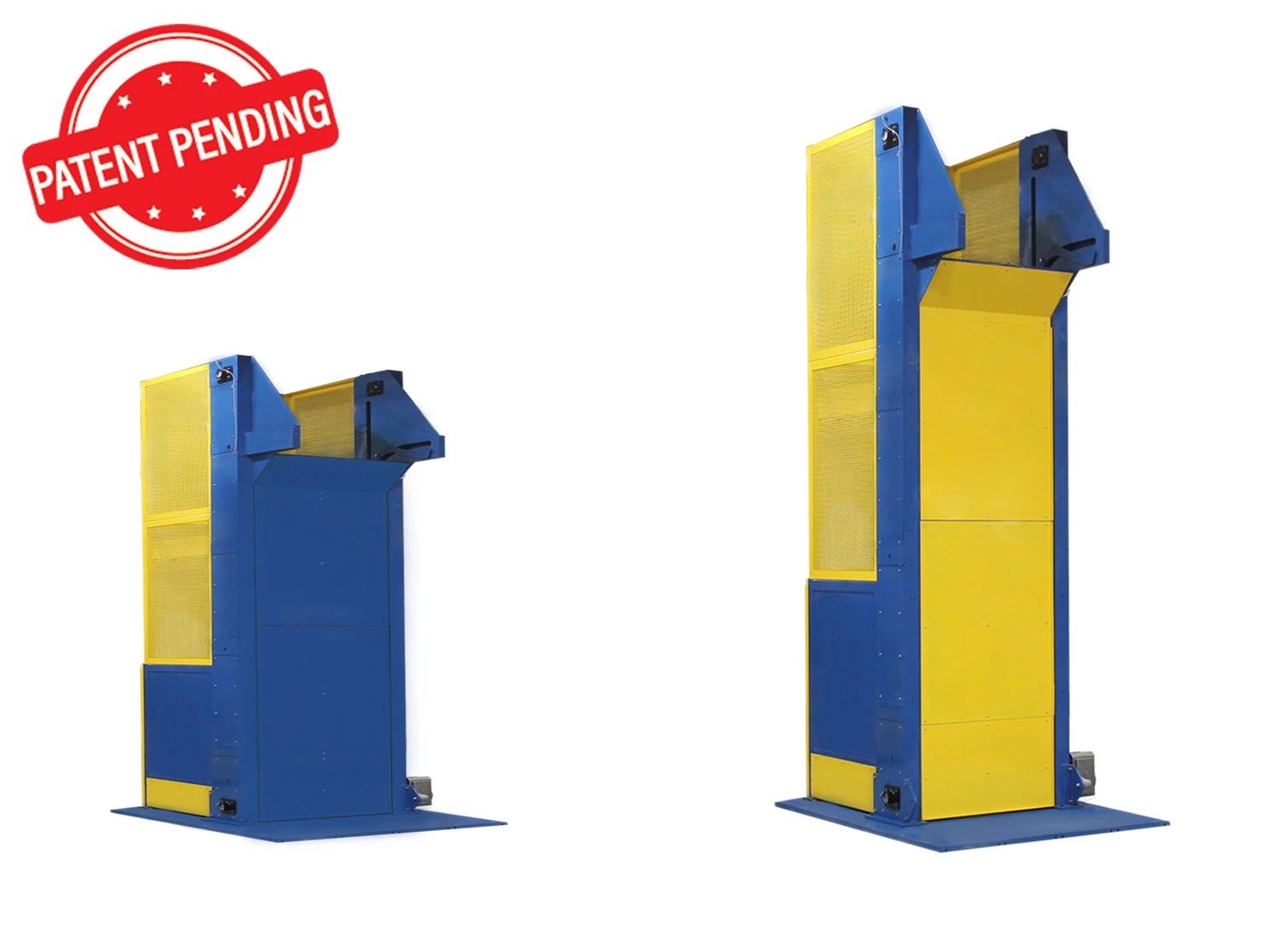

Image courtesy of Endura-Veyor Inc.

Alpena, Michigan-based Endura-Veyor Inc. says its new patent-pending Optimizer container dumper “defies immutable ceiling height, overhead clearance and floor space limitations while outperforming hydraulic dumpers in virtually every category.”

The company says Optimizer models are structurally and mechanically designed to overcome restrictions that limit typical dumpers from performing. Endura-Veyor says the hydraulics-free models offer a small footprint and operate more quietly than other container dumpers.

The company says the Optimizer models also significantly extend the horizontal reach to unload bulk and loose recyclable material.

Recylcers of electronic scrap, paper, old corrugated containers (OCC), rigid plastic and plastic film all can benefit from using the Optimizer, according to Endura-Veyor, as the load material into hoppers, shredders, balers and downstream equipment.

“A unique rotational design enables drums to rotate in a manner that evades overhead clearance interference, even with higher discharge height requirements,” Endura-Veyor says. The Optimizer models are driven by oversized dual chains with built-in redundancy designed to provide extra strength, lifting power and increased reliability in various recycling applications.

“There’s a new container dumper in town, offering revolutionary benefits that will tackle recycling industry challenges commonly associated with hydraulic container dumpers regarding speed, messy hydraulic fluids, space constraints and overhead clearance limitations,” the equipment company says.

Endura-Veyor has developed two model types: Optimizer and Hi-Lift Optimizer. Optimizers reach dump heights of up to 102 inches, while Hi-Lift Optimizers start dumping from heights of 9 feet (and can reach up to 20 feet), and include a full height enclosure as an added safety measure.

“What makes Hi-Lift Optimizers unique is their ability to cycle up to 50 percent faster and lift various container types higher than hydraulic lift and dump models,” Endura-Veyor says.

The two models also can be built with multiple discharge height positions, allowing them to feed various pieces of equipment, which can further increase achievable space savings and efficiency at a recycling plant, the company adds.

In terms of variability, by slowing or stopping the rotating drum at any position during the dump cycle, Optimizer dumpers can meter and control the flow of material that feeds shredders, grinders and granulators to avoid overfeeding and jamming, according to Endura-Veyor.

Standard controls include a programmable logic controller (PLC), a human-machine interface (HMI) screen or push buttons, an auto-lube chain and cycle tracking. Available structural options include custom drum sizes, chutes and features of gated enclosures, light curtains, and swing, slide or lift doors.

Endura-Veyor Inc. is a manufacturer of high-quality container dumpers, hinged steel belt, drag chain, fabric belt and magnetic separator conveyors, and other ancillary equipment used in scrap or loose material handling, recycling, manufacturing and distribution applications.

Latest from Waste Today

- US Senate backs reduced cuts to EPA

- ELV Select Equipment, Reworld aid NYPD in secure firearm disposal

- Waste Connections announces Q2 results

- Returnity and Cosmoprof to address reusable bag waste

- SWANA releases report on aging WTE facilities

- New economic assessment reveals cost benefits of California’s SB 54

- Premier Truck Sales & Rental opens new facility

- TeknTrash Robotics, Sharp Group partner on humanoid robot pilot